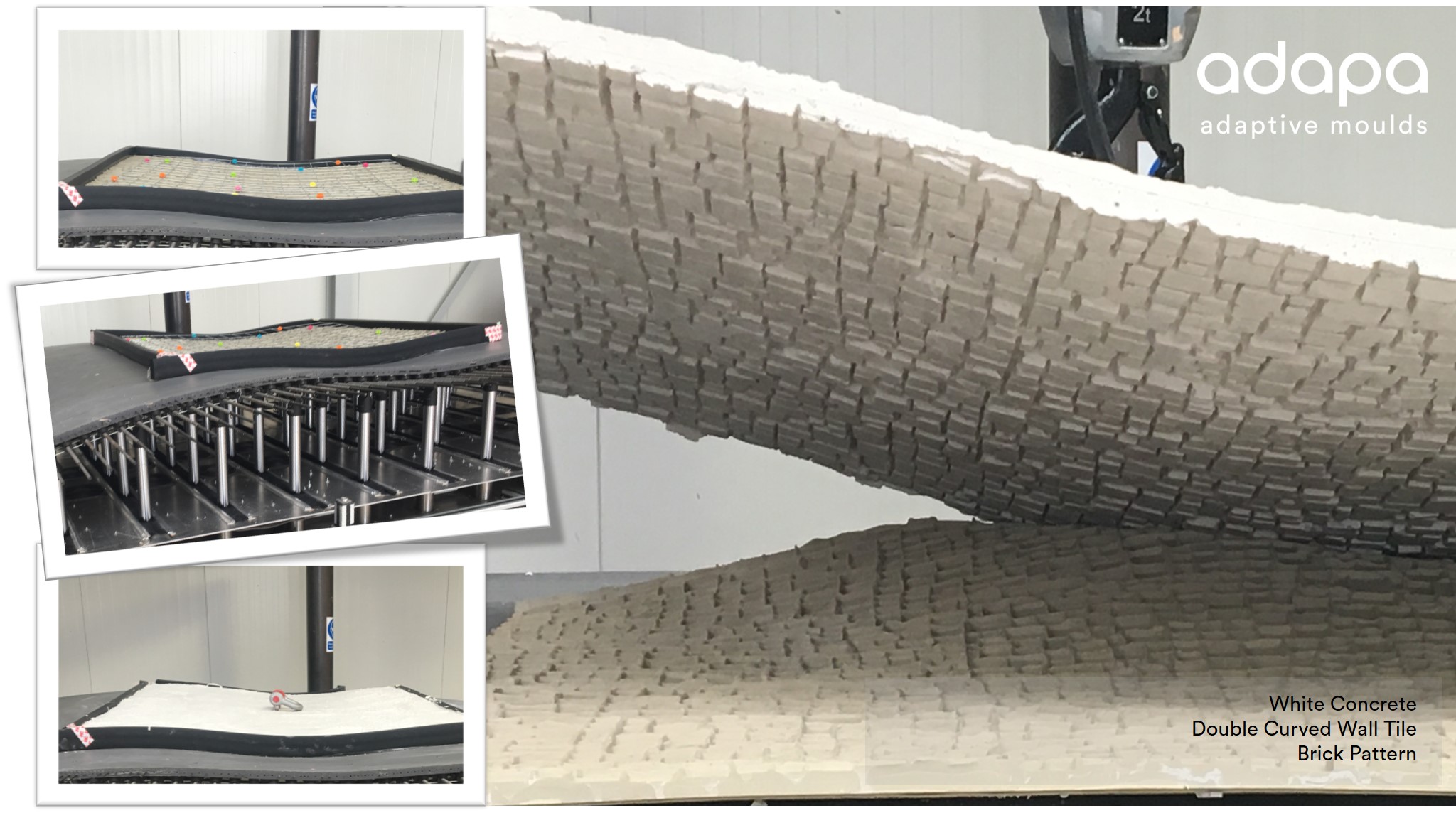

Concrete

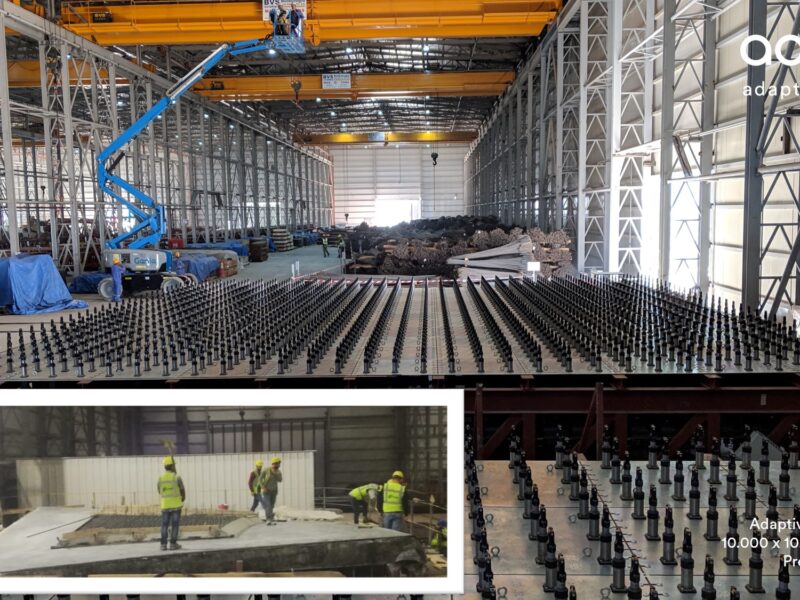

The Adaptive Mould for Precast Concrete, HPC, GFRC and GRG enables manufacturing companies to produce low-repetition curved panels faster, affordably and more sustainably than alternative techniques.

There is a rise in demand for curved and organic architecture, Concrete materials plays an important role across all sorts of constructions, and with an increasing awareness on flexible designs and decrease of environmental impact.

Concrete products hold unique flexible design capabilities and are in principle only limited by the boundaries of concrete mould.

Compared to the concrete value, one-off concrete moulds are quite expensive and mostly the re-use of moulds limit the architectural freedom.

The increase in demand for curved architecture demands for re-configurable technologies, that offer both the ability to create free-form architecture and be re-used to lower cost.

Adapa cooperate with experts from the field of concrete, to assist architects, advisors and fabricators in creating uniquely curved panels.

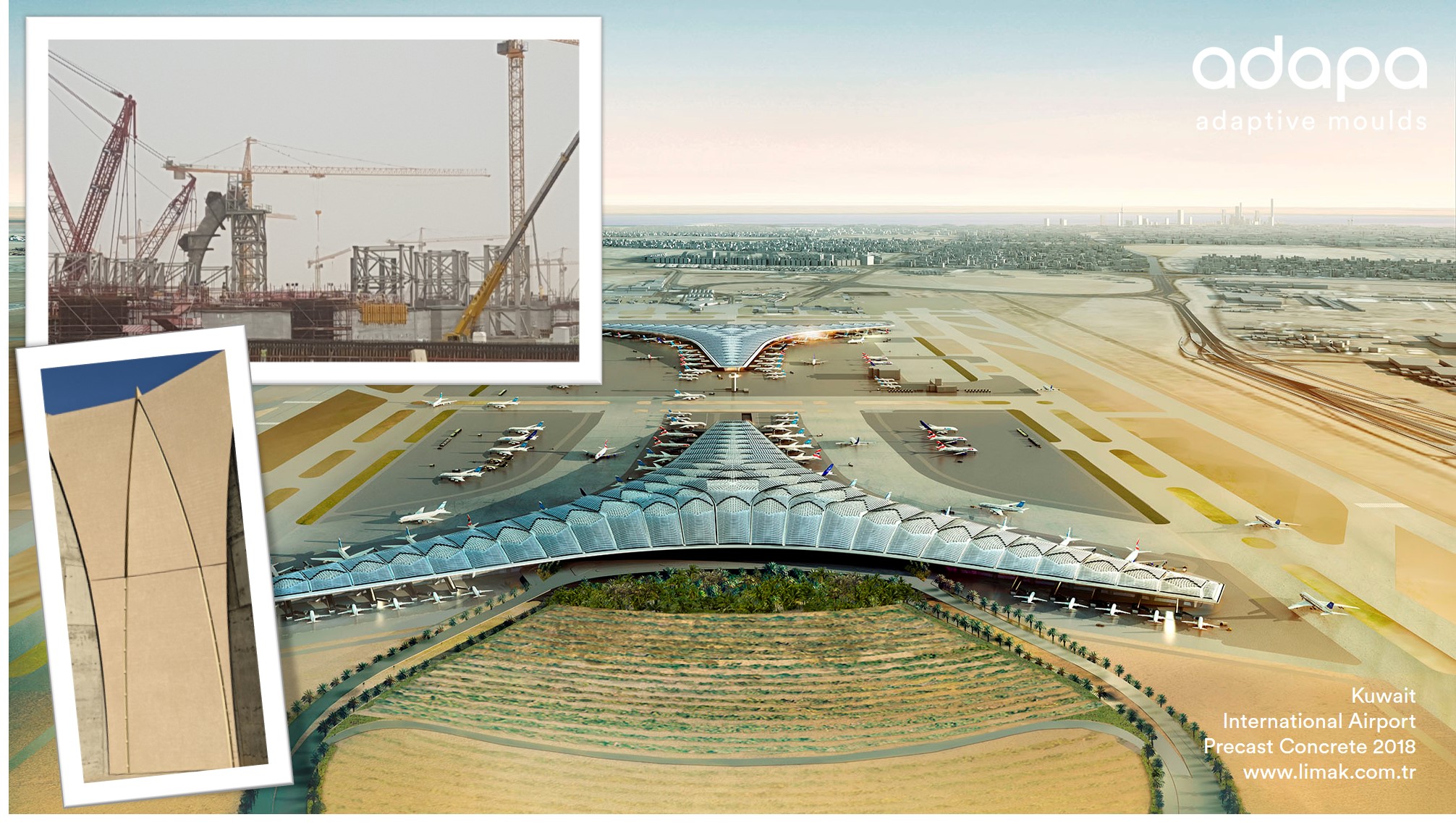

Reference Projects

Clients

Fast

One mould can take multiple shapes, and it can do so within minutes. This means that you have:

Affordable

The Adaptive Mould eliminates the need for manufacturing unique tooling for every panel and because of this you have:

Sustainable

The Adaptive Mould significantly reduces your potential waste of disposable moulds, which means that you have:

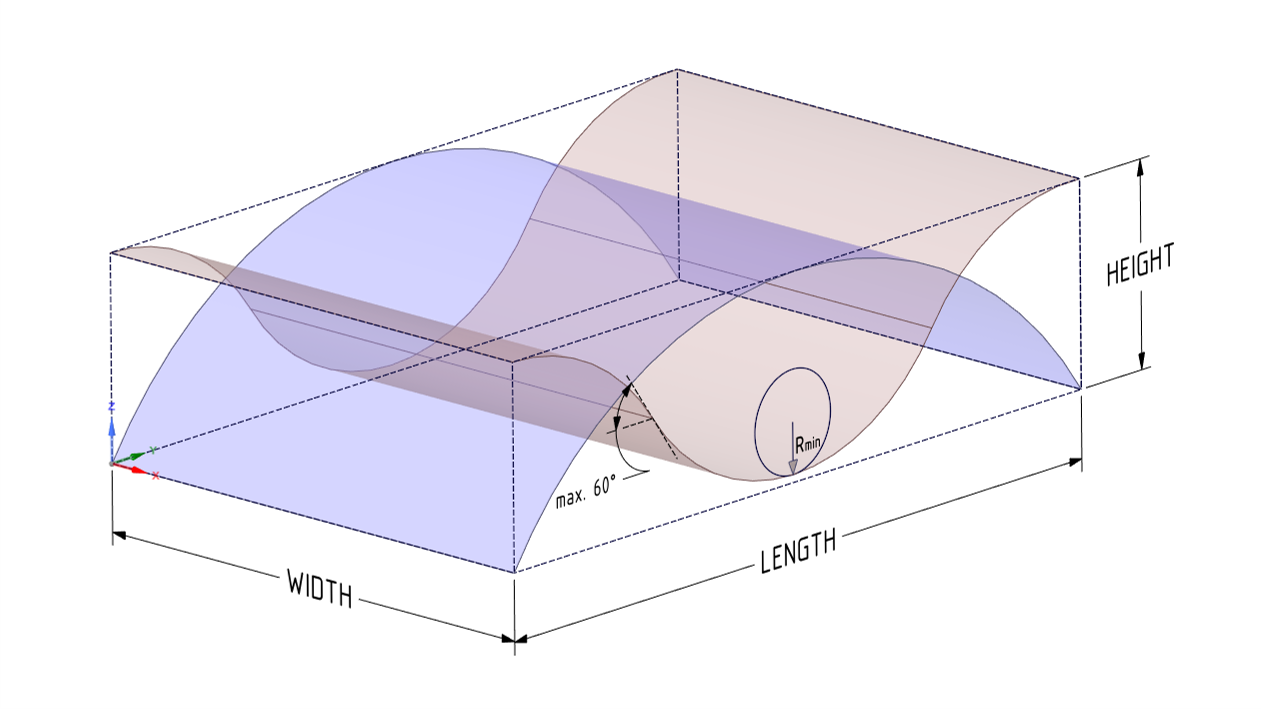

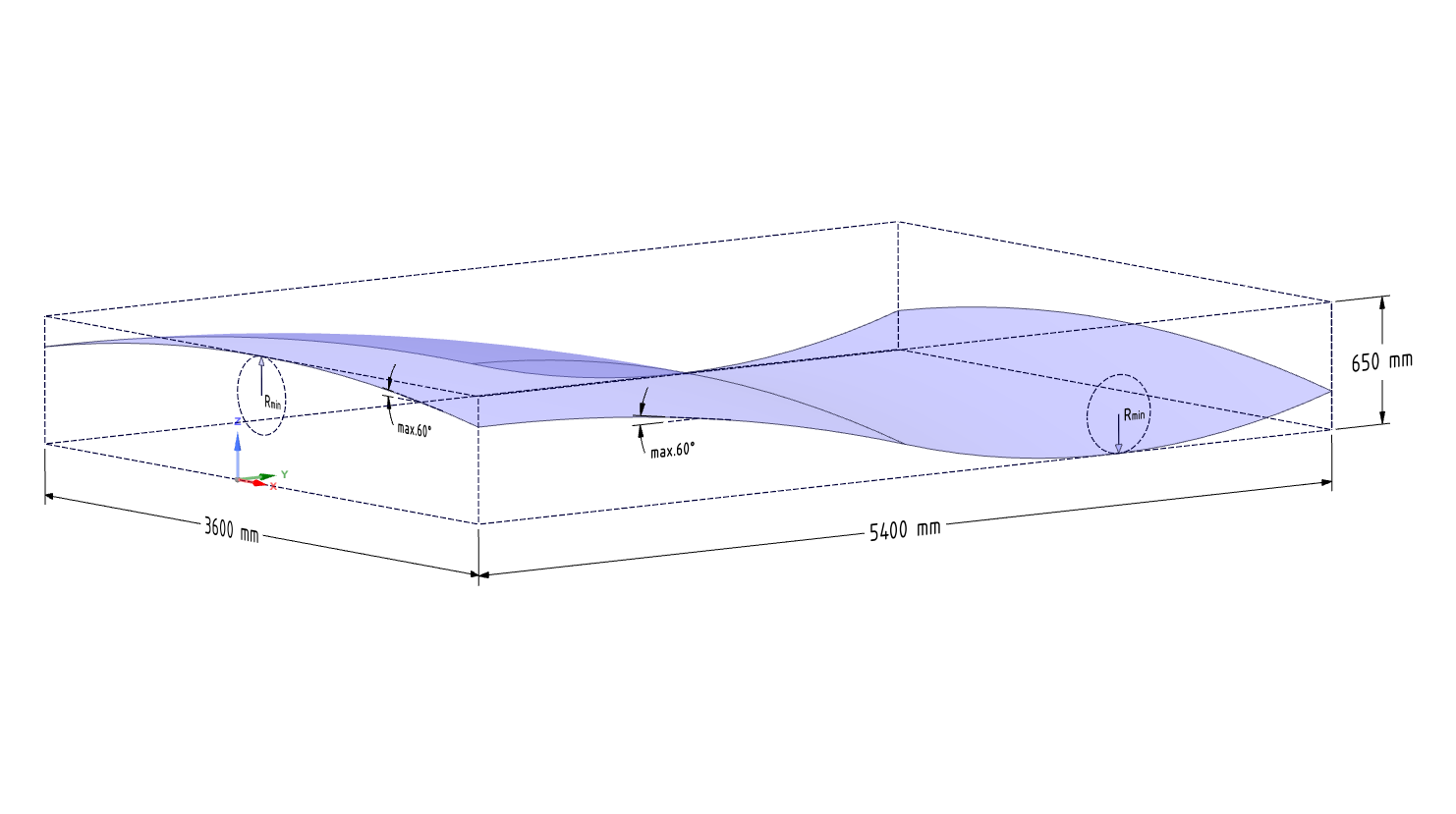

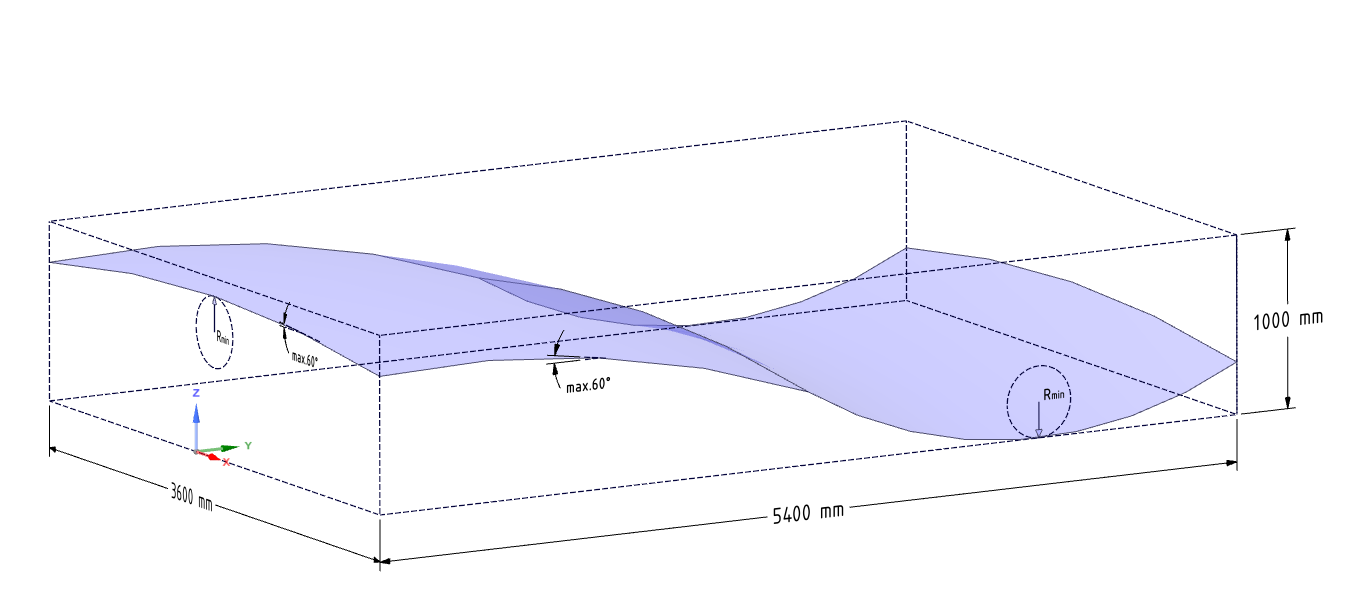

There are three different adaptive mould types that can be used for curved concrete manufacture:

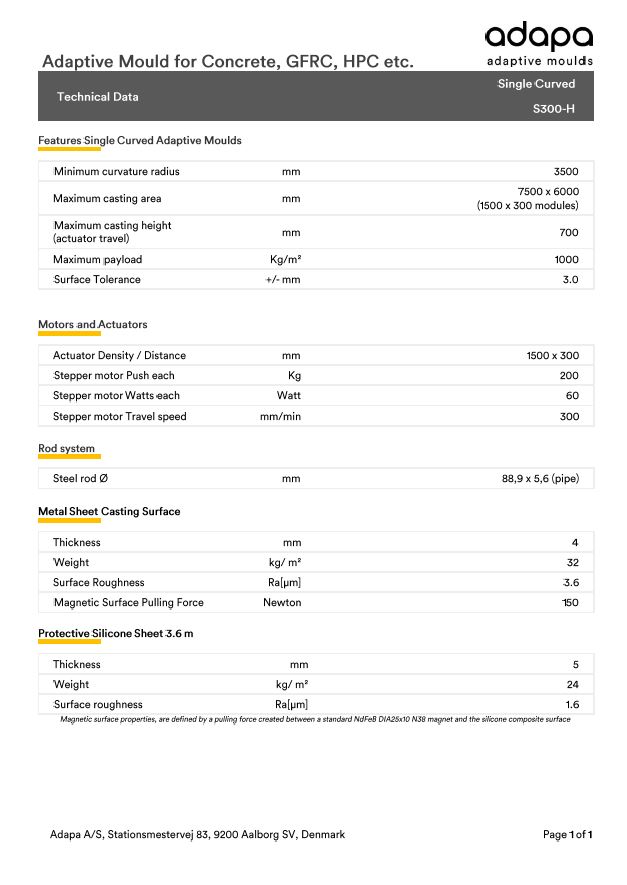

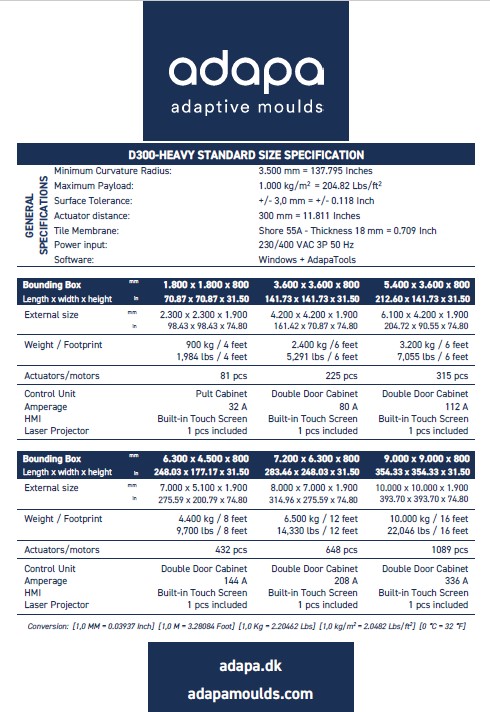

Technical Data for Single and Double Curved Adaptive Mould Types for Precast Concrete, HPC and GFRC

Main Technical Features

S300-H

D300-H

D300

Minimum curvature radius

mm

3500

3500

1800

Maximum casting area

mm

7500 x 6000

9000 x 9000

5400 x 3600

Maximum payload

Kg/m²

1000

1000

225

There are more advantages that can be achieved:

Multi Stage Forming

The flexible properties of the Adaptive Mould allow for multi-stage forming, including a process such as the following:

High precision

The Adapa Tools software eliminates the need for manual measuring and support you to benefit from the advantage of:

Collaborative Technologies

The Adaptive Mould is designed to handle surface temperatures up to 140o C and collaborate with several technologies: