MAGNETIC SHUTTERING SYSTEM

For adjustable angular support of casting sides on adaptive moulds

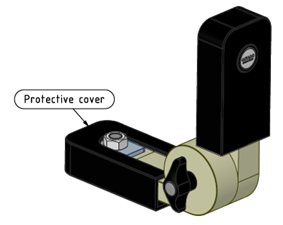

The magnetic angular support serves as an adjustable supporting element in a shuttering system for casting on adaptive moulds.

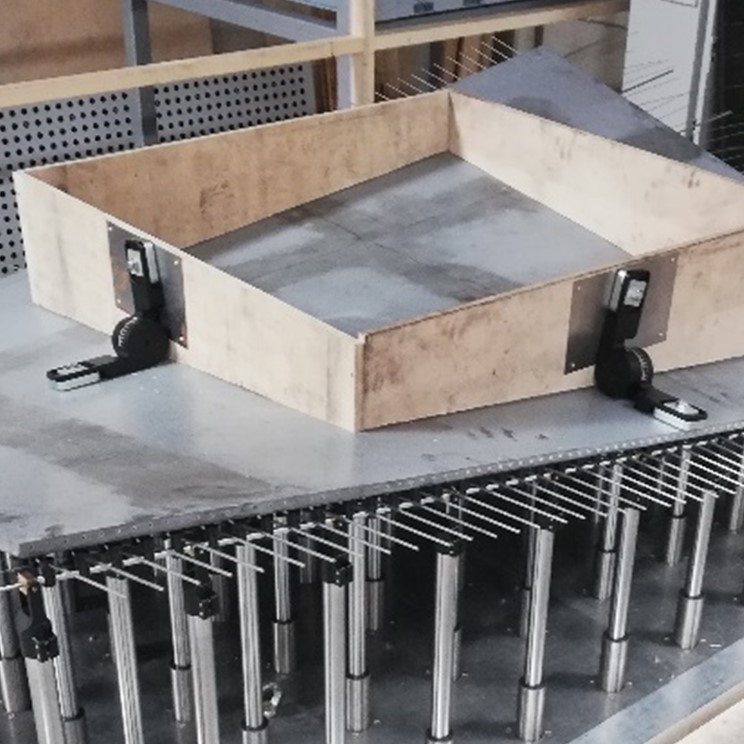

Typically, it is used to support curved wooden (or alike) casting sides that are CNC cut based on the panel 3D files.

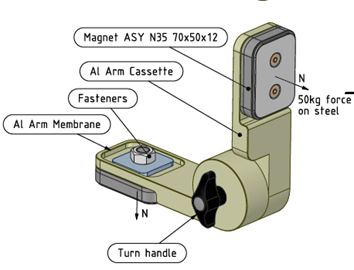

A powerful magnet is used to fix it to the casting membrane, and it can be fixed to casting side using the standard mounted magnet or customized solutions.

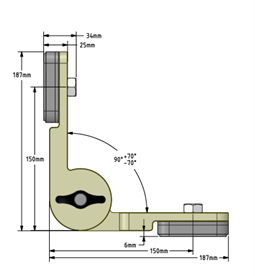

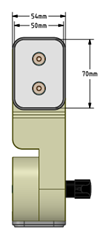

The magnetic angular support is adjustable device that can be set at any angle between 20 and 160 degrees and locked in position with a handle installed on its side.

The force of the magnets against steel is 500N (equivalent to 50kg). The force of the magnet against the membrane on an adaptive mould is 100N (equivalent to 10kg). The case specific load-pressure capability depends on the specific supported angle and the casting surface angle, fastening of the turn handle, membrane, and use of protective sheets as well as the fixture to and capabilities of the casting sides.

In general, we recommend supporting traditional casting sides with a minimum of one magnetic angular support each 50 cm.

The casting sides should also be supported by other means. This is typically done using traditional ways of constructing cassettes and/or fixpoints between casting sides, reaching from one side to another, to further support the casting side.

Specification

| Curvature radius (min.) R1800mm |

| Magnetic strength Vertical 10 kg on adaptive mould membrane, 50 kg on steel |

| Magnetic strength Horizontal depending on curvature, side angle etc. |

| Casting height 20 cm, recommended minimum distance 30 cm |

| Casting height 10 cm, recommended minimum distance 50 cm |

| Weight each 1,3 kg |