The definition of surface roughness

Surface beauty and definition of surface quality

When delivering the final product our customers must perform in presenting a surface of the manufactured product, that fulfills the final customers specifications and visual inspection. Our customers manufacture panels and surfaces based on different materials and processes, and we strive to deliver the best and most controllable surface quality of our adaptive moulds.

We recognize that the appearance of a surface is different based on the individual eye, setting of light, color of material and of course the difference in a chosen pattern or not. Our engineers are often consulted in the process where customers try to determine how smooth or rough a surface will turn out. It is however not easy to assist in the planning of how to make the right surface, as it is the final customers expectation and perception that determines the satisfaction on surface quality, or beauty.

Beauty is in the eyes of the beholder, and to be quite honest our adaptive moulds do not make surfaces look any better than any traditional mold. Our adaptive moulds just make it easier, faster, and more affordable to make curved surfaces.

Adapa’s definition of surface roughness

Surface

A surface is a boundary that separates an object from another object or substance. In order to better understand the measurement of surface finish, we divide surface into two sub-types.

Real Surface

It is the actual boundary of an object. It is produced as a result of the process that created the surface.

Measured Surface

A measured surface is a representation of the real surface obtained with some measuring instrument. This distinction is made because no measurement will give the exact real surface.

Surface Imperfections

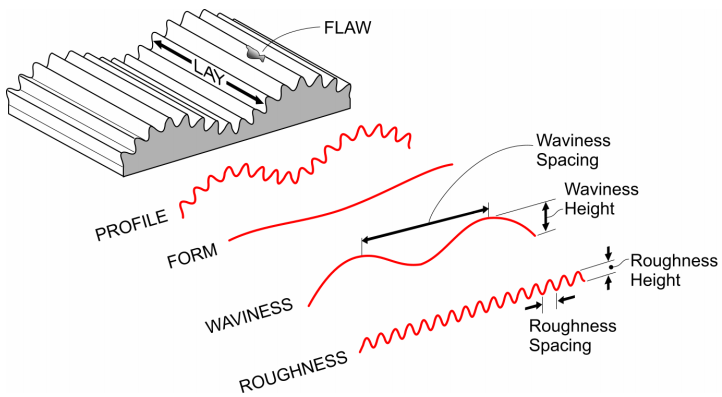

Referring to the figure, you can see the magnified view of a sample surface and the characteristics of a surface.

Surface is made of

- Roughness

- Waviness and

- Lay

The two surface characteristics Roughness and Waviness are quite important to Adapa´s definition of the casting surface quality on the membrane surface, while Lay is not influencing.

Roughness includes the finest (shortest wavelength) irregularities of a surface. Roughness generally results from a production process or material condition.

Ra (way to define roughness) – Average Roughness Also known as Arithmetic Average (AA), Center Line Average (CLA), Arithmetical Mean Deviation of the profile. The average roughness is the area between the roughness profile and its mean line, or the integral of the absolute value of the roughness profile height over the evaluation length.

Waviness includes more widely spaced (longer wavelength) deviations of a surface from its nominal shape. Waviness can be a result of design, production, assembly process and storage irregularities.

Waviness is defined by its Waviness Spacing (WS) and Waviness Height (WH).

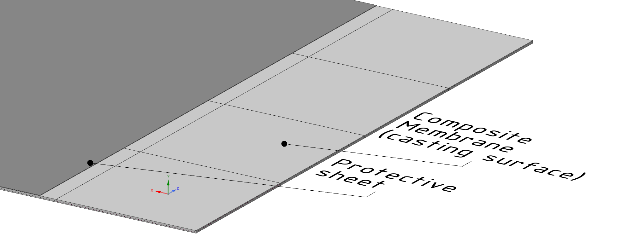

Adaptive Moulds – casting membrane imperfections definition

Composite membrane is the base that provides the desired shape. It is also quite expensive part of the machine, so it is important to protect it with another thin layer of protective sheet. The user can choose to cast different sorts of materials on top of the Composite membrane or protective sheet. The recommendation in any case is to use protective sheet when doing so.

Roughness of the Composite membrane varies between Ra3.2 and Ra6.3. Protective sheet on the other hand has roughness of Ra1.6. This is one other benefit of using Protective sheet, that is usually provided together with the machine!

Waviness, the maximum allowable, is defined by WSmin.=45mm and WHmax.=0.3mm!